A lot of product ideas don't work out. Sometimes they're infeasible. If not, you build it and find out it sucks. If not, you build more and your customers say they suck. (Or so few say that it doesn't suck that there's no reason to make any more.) If not, then you've got a winner. Congratulations.

Still, most times you fail. But you have to keep trying because that's the only way to tell for sure. So you have to minimize the expense of each attempt.

One avenue I've taken for making low-cost products is the StickIt! board with it's add-on modules. The modules are small (less than two square inches) and perform some limited function (think LEDs, buttons, VGA, ADC, etc.) in service to an FPGA that does all the heavy lifting. The limited functionality and small size makes the modules easy to design and cheap to produce.

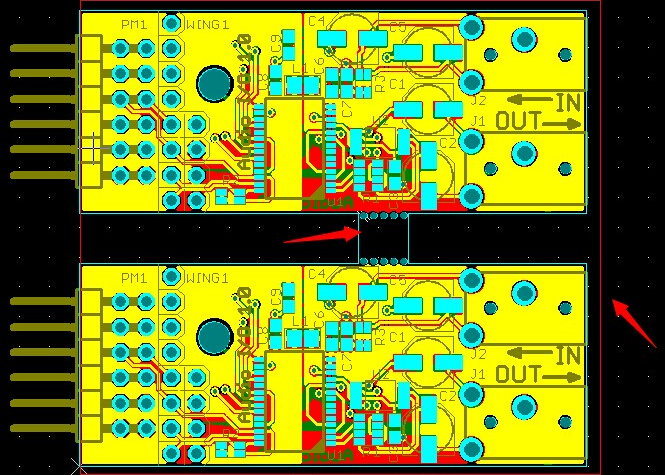

I chose the 0.8" width of the StickIt! modules to mimic the width of many of the Digilent PMOD modules. And the length was chosen so they would fit into the low-cost, small 5 cm × 5 cm panel size offered by places like Itead and Seeed. Using a snap-off tab, I can lay out a simple 2 × 1 board array that fits into a single panel like this:

The total cost was $10 for 10-12 panels and $4 for shipping with a total turn-around time of 19-26 days from Gerber submission to receipt of the panels. So for $14, I could get 20-24 StickIt! module PCBs in less than a month.

That was great until last year when Itead started rejecting my Gerber files. Essentially, they didn't like manufacturing arrays of boards connected by snap-off tabs. They would do a single board per panel, but that halved the number of boards I got for my $14. That's not a deal-killer, but once you get used to sub-$1 PCBs, you don't want to go back.

So I moved over to Seeed who had no problem with accepting and manufacturing my little PCB arrays. At least, they didn't for the very first one I sent! After that, my next array was rejected. They would do it, but only if I used a V-score instead of snap-off tabs. And the cost for V-scoring more than doubled the price, so I would have been better off just doing a single board per panel.

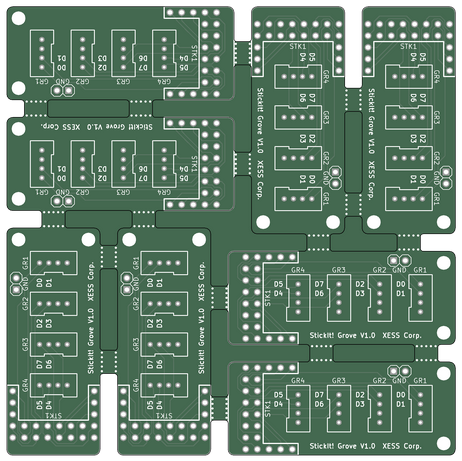

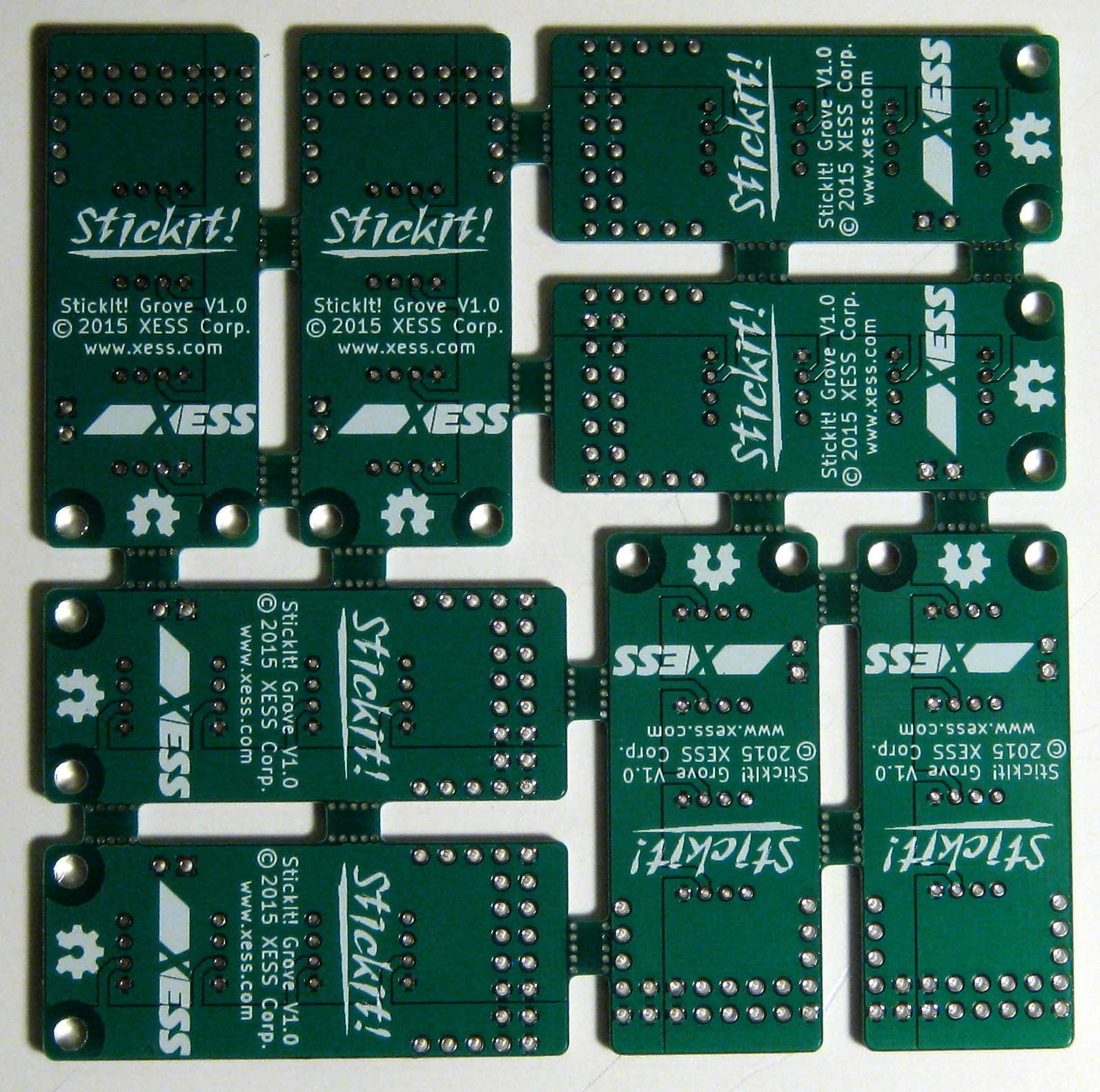

So I went in search of another manufacturer. I eventually hit upon Dirt Cheap Dirty Boards who go by the tag line "No bull, just crappy PCBs". Now, that may give you pause as to the quality of the panels you'll get from them, but the customer testimonials were ecstatic and they said they could do 5 mil trace/space etching! (Seeed and Itead only claim to do 6 mil and recommend 8.) They offered a 5 cm × 5 cm panel for $14 and a 10 cm × 10 cm panel for $25. (All their prices include shipping, so they're equivalent to the prices charged by Seeed and Itead.) The 10 cm × 10 cm panel is less than twice the cost of the 5 cm × 5 cm panel but offers 4× the area, so I figured why not go for broke and make a bigger panel with eight module PCBs on it? That would bring the per-PCB price down even further and it's no more likely to get rejected than the smaller panel. So I submitted Gerber files for this:

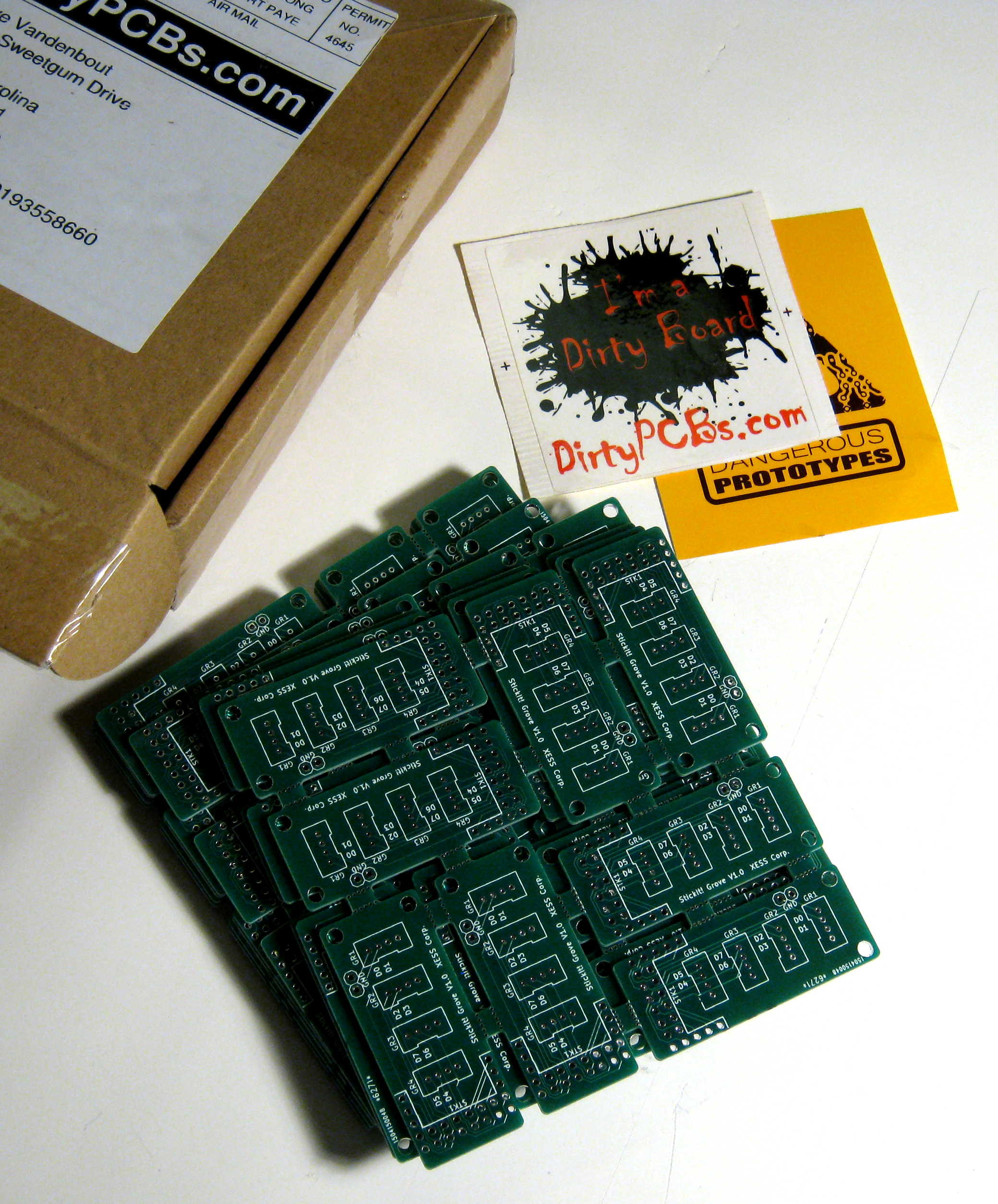

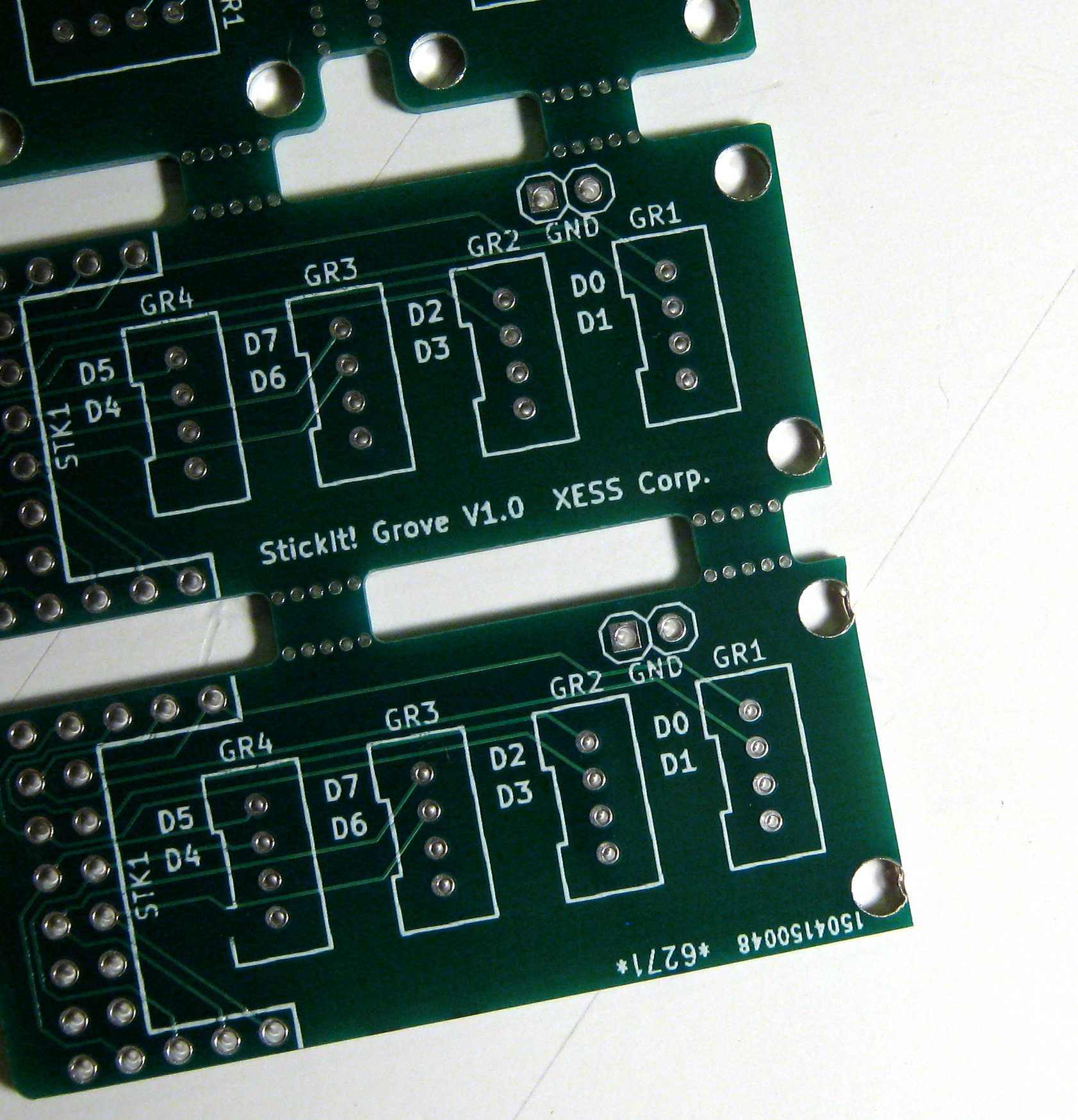

That is a really funky board outline and there are nine internal slots, some of them very oddly shaped. I wouldn't have blamed Dirty PCBs for rejecting it, but 24 days later I got this in the mail:

The panels looked pretty good.

| Front | Back |

|---|---|

|

|

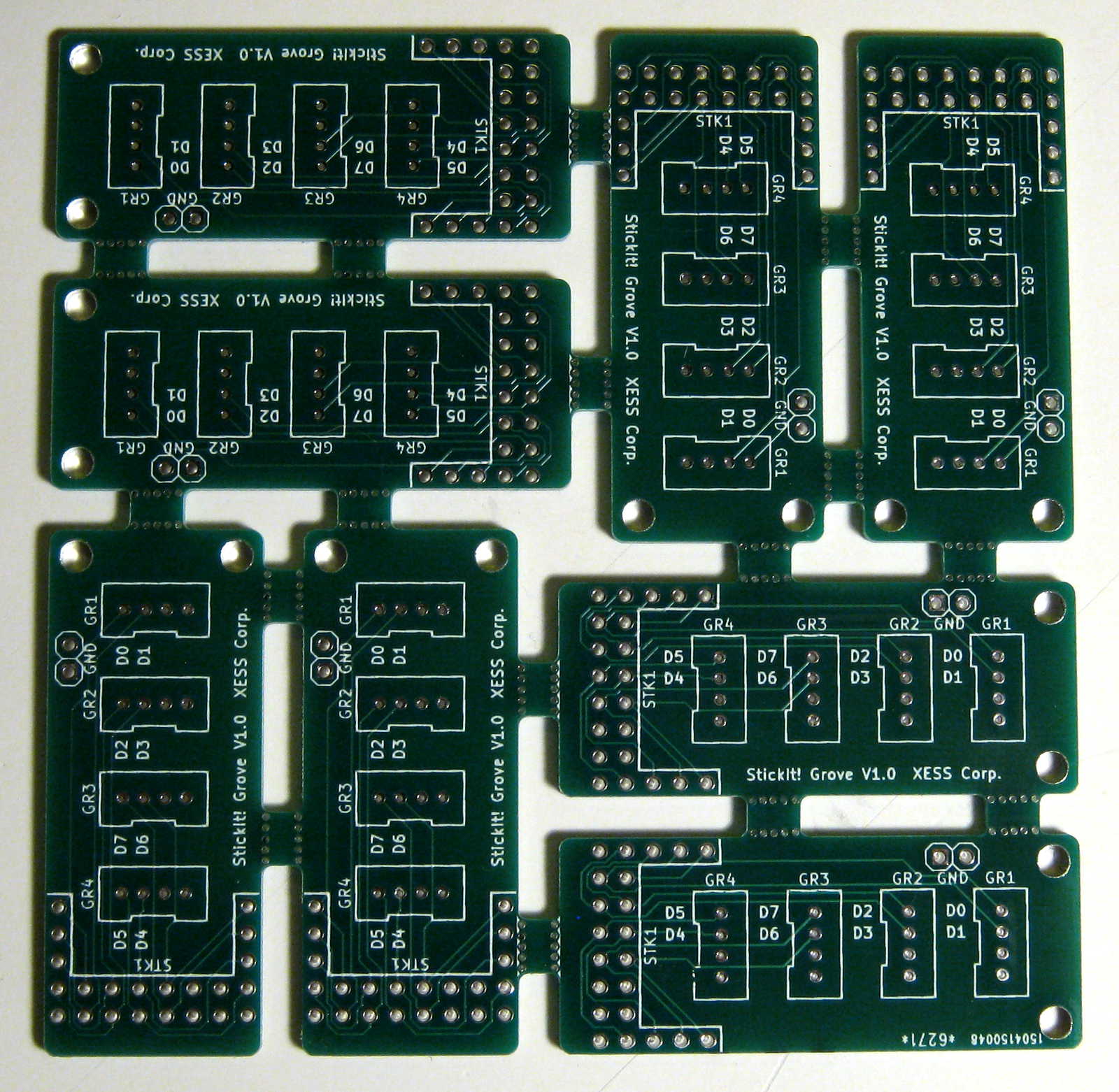

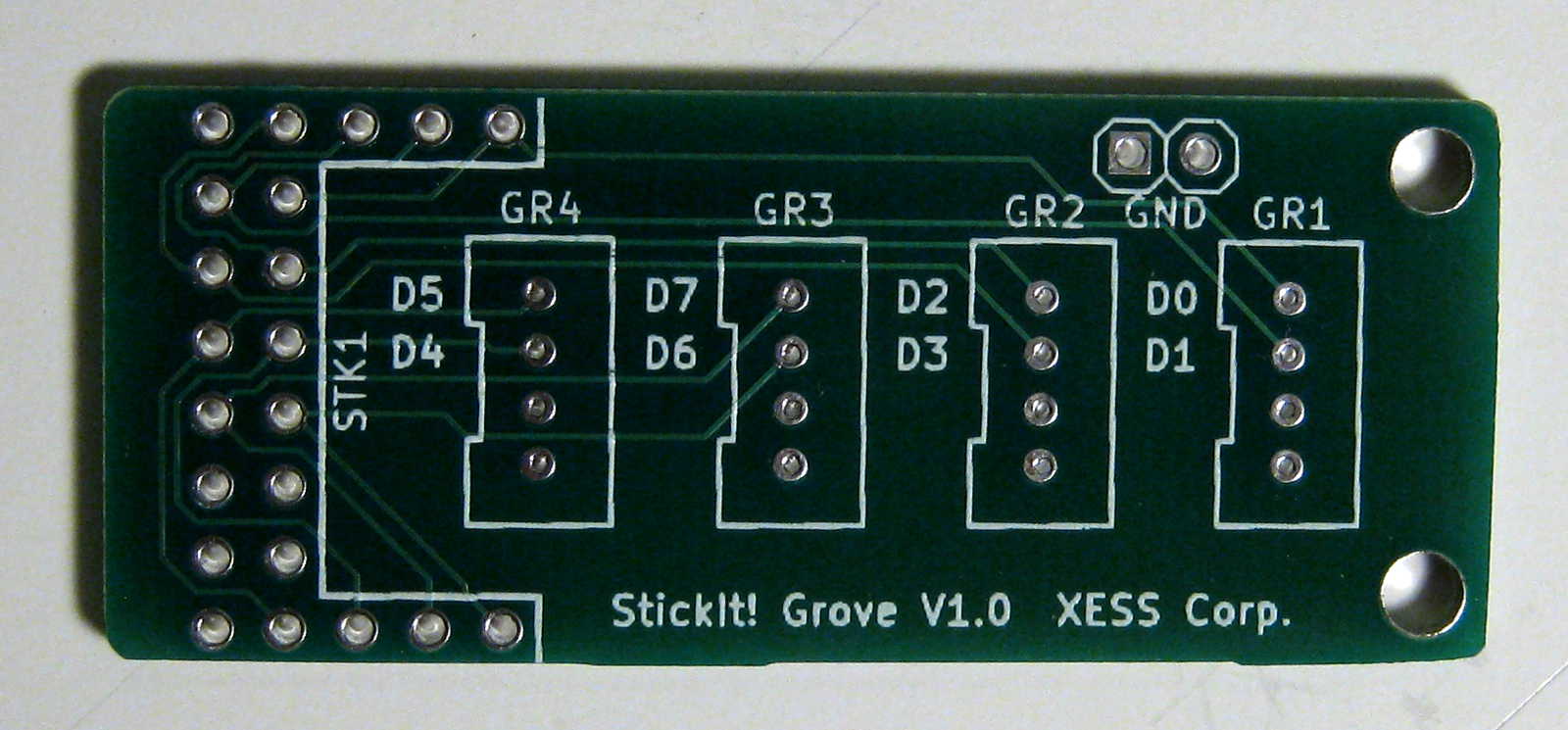

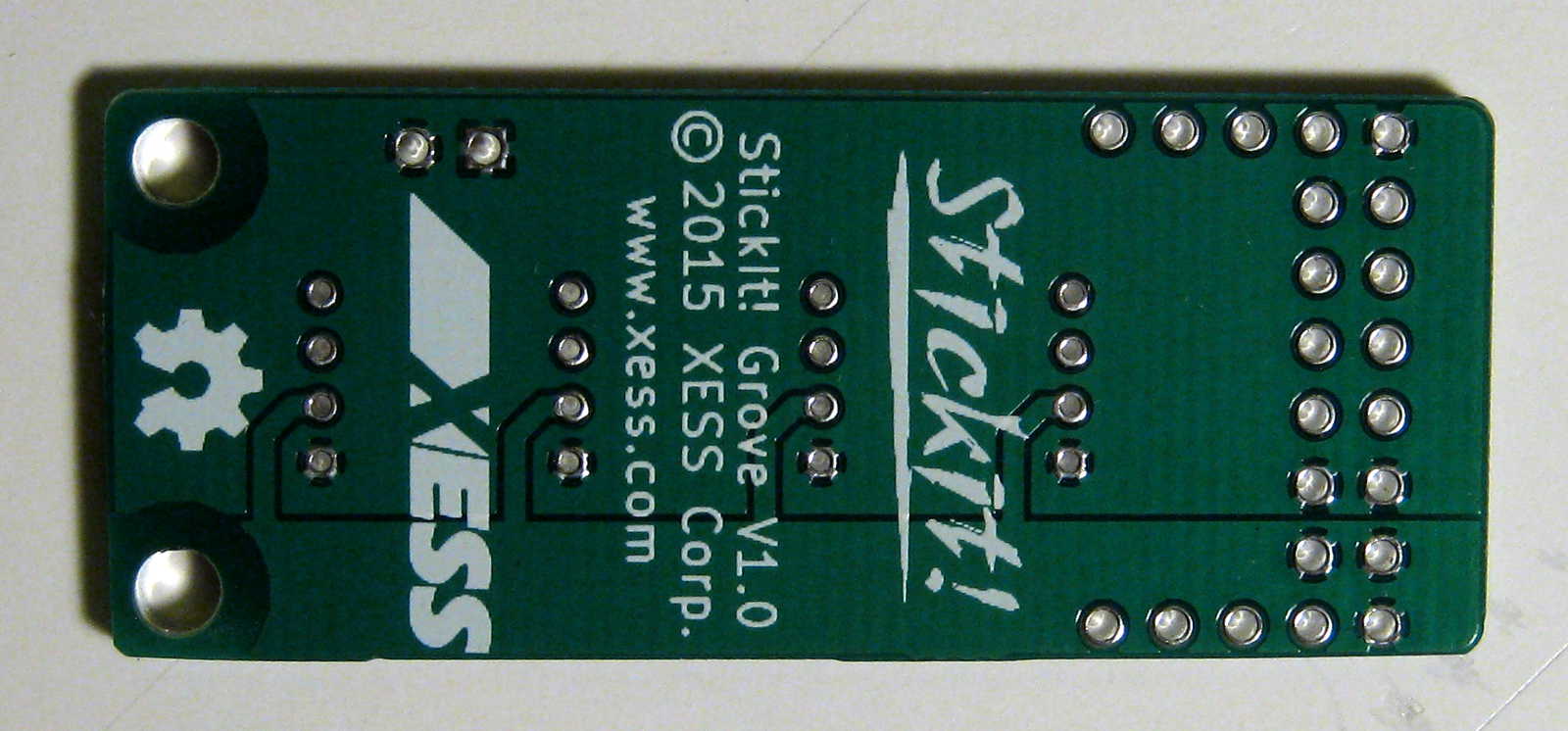

After buffing-out the mouse bites left by removing the snap-off tabs, the individual boards looked OK.

| Front | Back |

|---|---|

|

|

Lest you think everything was all sweetness-and-light, Dirty PCBs did nick a few of the panels when they were being routed. I lost five individual boards from this.

I ordered ten panels, but I received eleven which gave me 88 individual PCBs. Subtracting the five damaged PCBs left me with 83 usable boards for a per-board cost of 30¢.

At least, they would have been usable if I hadn't screwed up! I didn't have a datasheet or any physical copies of the four-pin Grove socket to measure, so I used a footprint from someone else's design. When the actual sockets arrived, the holes were a little too small and the plating a little too thick so the socket leads didn't fit. I'll have to correct the socket footprint and make another batch.

Luckily, that's only going to cost me $25.

Share on Twitter Share on Facebook Share on Reddit

Comments

What a great deal.

Link / ReplyCan you comment on the size and placement of the holes you used for the breakaway tabs?

I use 20 mil holes spaced 40 mils apart. I've found you can use 80 mil-wide tabs with two drill holes and they still hold the boards securely and break away easily.

Link / ReplyGreat idea. Ifirst itme have seen this type of PCB designs. Thanks for sharing.

Link / ReplyNew Comment